| |

|

|

|

|

Concrete Performance Enhancer (YL-800) is a simple, effective, dust-free surface wear-resistant enhancer that could be applied to all types of concrete floors.The content is a colorless transparent liquid, odorless (low VOC emissions), non-toxic (safe for children), and non-combustible, can effectively permeate concrete, lime and cement surfaces to induce crystallization effects and enhanced the concrete material from within. Not only does the floor hardens, the formed crystals would tighten the floor structure and ultimately strengthening the floor up to several centimeters in surface depth, repelling moisture, and effectively blocked corrosive chemicals ingredients such as oils, acids, alkaline, alkaline penetration. |

International Packaging

Packaging for China region

|

| |

|

Perpetual crystal surface |

|

|

Seven days after the application of Concrete Performance Enhancer, the crystals forms around the concrete floor surface, filling in the spaces between the fine particles within the concrete that cannot be seen with the naked eye. Once the crystallization process is complete, the surface density increases dramatically and gives off a natural gloss shine. Continuous usage will build the shine and gloss on the surface, without any wax applied. |

|

Applicable to all concrete / aggregate surfaces |

|

|

Our Concrete Performance Enhancer can be applied to different concrete or aggregate conditions, washed granolithic finish, millstones and gypsum, plaster floor, hardener and any mixture of sand and cement for building and construction material. |

|

Economic and long-lasting |

|

|

Epoxy resin coating floors, often need to be re-coated from the weathering and surface stripping. CPE with the crystalline surface is weather resistant, and as long-lasting as the construction. Just one, single application to your concrete flooring, you get unbelievable durability and endurance that can last up to a lifetime. |

|

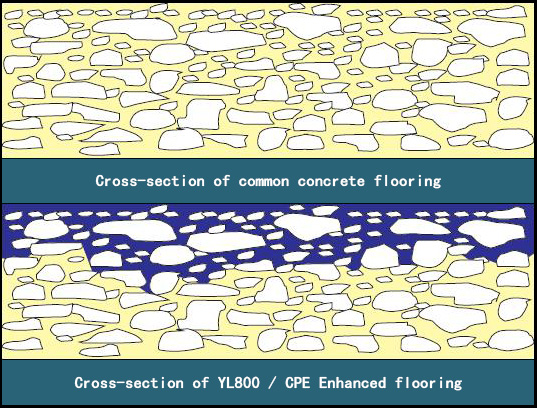

Densify concrete structure from within |

|

|

Concrete Performance Enhancer, permeates through the concrete surface and induces natural chemical reaction with the concrete structure from within. Major advantages include significant increase in the density of the structure, thereby improving the overall strength of concrete, and help seal the concrete within its structure and build water and weathering resistance. No dust and sand will be formed from normal use, and best of all, scratch-free and pit-free surface. |

|

Zero maintenance |

|

|

Floor or wall surfaces treated with CPE prevent sanding and becomes dust-free, free of mold and moisture, repels moss, requiring little or no surface cleaning or maintenance. |

|

Energy efficient and carbon-reducing |

|

|

Building materials in the post-millennium era has the responsibility of being green and help reduce carbon emissions. CPE is tested non-toxic, odorless, and non-combustible. Application is simple and efficient, CPE treated surfaces also enhance the service life of the concrete without altering its original pH level. In comparison to other sealants or coating materials such as epoxy resin, CPE has great economic and environmental benefits. Furthermore, CPE application involves in no construction waste, toxic free emissions, and most importantly, pollution free. CPE as a product and its application methodology is in line with the modern energy conservation and environmental protection standards. |

|

|

| |

|

|

|

High speed road |

|

|

|

Dramatically increase service life of concrete, shear resistance, impact,

abrasion resistance, saving maintenance costs. |

|

|

|

Industrial plants, parking lots, malls |

|

|

|

More durable than epoxy resin floor, and hardener layered flooring, giving an antistatic,

sand-free, wax-free, perpetual gloss and shine.

|

|

|

|

Pharmaceutical and food processing plant |

|

|

|

Green building material, waterproof, sand-free, zero pollution. |

|

|

|

Gas station, heavy machinery maintenance warehouses |

|

|

|

Prevents oil and chemical erosion, easy to keep clean and extend the service life of

the original concrete flooring. |

|

|

|

All concrete walls and buildings |

|

|

|

Waterproof, corrosion resistance to acid rain, acid, moisture, mildew, and prevent efflorescence. |

|

|

|

Building roof, ceiling and basement |

|

|

|

Improve waterproofing requirements of buildings, enhance concrete compactness, reduce cracks,

prevent roof leaks and the infiltration of moisture.

|

|

|

|

|

|

| |

|

|

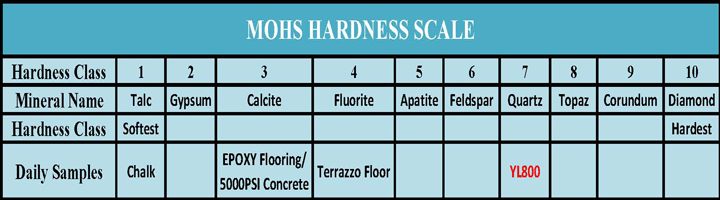

Mohs Hardness Scale Collection |

|

|

|

|

|

Mohs Hardness Scale |

|

|

|

|

|

Note: the hardness of the knife is 5.5; copper coins is 3.5-4; nail is 2-3; glass is 6. |

|

| |

|

| |

|

|

| |